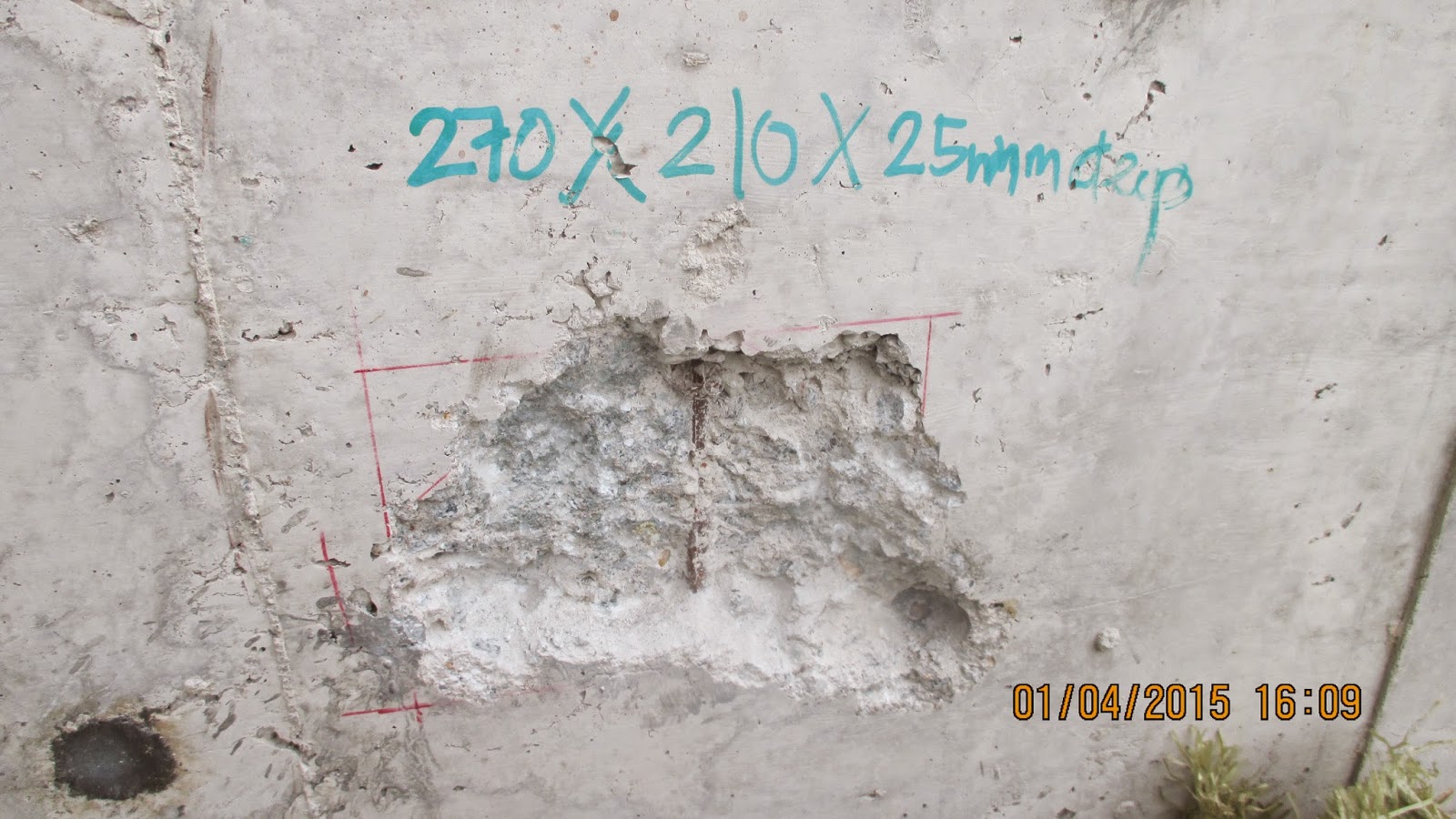

The Defects

|

| Location 1 |

|

| Location 2 |

Identifying Concrete Defects

Many concrete defects are immediately recognized and others are not. Being able to properly identify the defect will aid in choosing the best evaluation methods and subsequently the best repair methods. Concrete defects can be broken down into four broad groups based on visual observation: deformation of the surface, cracking of the surface, disintegration of the surface, and other defects.Deformation of the Surface

Three defects cause deformation of the concrete surface, but may not exhibit any other symptoms. The first is curling or warping. This is the deformation of the edges and corners of a slab-on-ground in the absence of any loads. When caused by moisture, this deformation is called warping; when caused by temperature, it is called curling. The second defect is the delamination of surface mortar from underlying concrete. It is difficult to visually observe a delamination before it becomes dislodged from the surface. However, in small discrete locations, the surface may exhibit convex rising called blistering. Blisters are generally isolated, but may be closely spaced and can combine to form a large blister or delamination. A third defect occurs when isolated low spots on the surface collect water and have no means of drainage. These surface water pools are known as “birdbaths.” |

| Most affected damages due to congestion of the rebars |

|

| measuring width |

|

| measuring height |

Cracking of the Surface

Cracks appear in concrete for many reasons. Some cracks can appear as secondary symptoms of other defects, such as a long rounded crack following the structural failure of a warped slab. Discussed here are cracks that are primary symptoms of distress, caused by volume changes and structural failure.Shrinkage cracks have many different looks and can be difficult to distinguish from cracks caused by other mechanisms. Discreet, parallel cracks that look like tearing of the surface are caused by shrinkage while the concrete is still fresh, called plastic shrinkage. Fine random cracks or fissures that may only be seen when the concrete is drying after being moistened are called crazing. This defect may also become evident when a translucent coating is applied to the concrete surface. Cracking that occurs in a three-point pattern is generally caused by drying shrinkage. Large pattern cracking, called map-cracking, can be caused by alkali-silica reaction within the concrete. Structural failure cracking may look like many other types of cracking; however, in slabs they are often associated with subsequent elevation changes, where one side of the crack is be lower than the other.

Disintegration of the Surface

Disintegration of the surface is generally caused by three types of distress. When laitance forms on the surface, it is called dusting. This can be caused by a number of reasons, which include carbonation of the surface by unventilated heaters or by applying water during finishing. Raveling or spalling at joints occurs when aggregates or pieces of concrete from the joint edges are dislodged. The last form of disintegration is the breaking of pieces from the surface of the concrete generally caused by delaminations and blistering. Popouts are conical fragments that come off the surface, typically leaving a broken aggregate at the bottom of the hole. Popoffs, or mortar flaking, is similar to popouts, except that the aggregate is not broken and the broken piece is generally smaller. Flaking of the concrete surface over a widespread area is called scaling.

Evaluating Concrete Defects

Visual examination typically does not provide enough information to determine the cause or causes of a defect. In some cases, it may not provide evidence of a defect at all. In order to narrow the scope of an investigation to probable causes and suitable repair methods, the appropriate information factors and the proper evaluation methods need to be identified.

Evaluation Information Factors

Information about the structural capacity and loading of a concrete placement may provide important details as to the cause of defect or failure. The thickness and the loading of the slab will allow assessment of the in-place strength versus actual loads in use. Crack properties, such as its width and location of reinforcement, will provide information that can be used to determine activity and origin. Joint characteristics, such as spall dimensions and activity, will provide information on the effectiveness of the joint.

Evaluation Methods

The visual examination is typically the first method of evaluation used as it identifies that a problem exists and if further evaluation is necessary. Surface elevation profile measurements taken according to ASTM E1155, Standard Test Method for Determining FF Floor Flatness and FL Floor Levelness Numbers, can be used to quantify deformations of the surface. Sounding according to ASTM D4580, Standard Practice for Measuring Delaminations in Concrete Bridge Decks by Sounding, can locate delaminations. Coring can be used for a variety of reasons including strength testing according to ASTM C42, Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete, or petrographic examination according to ASTM C856, Standard Practice for Petrographic Examination of Hardened Concrete.

Other Defects

Other defects include discoloration of the concrete; bugholes, which are small voids in the surface of vertical concrete placements, and honeycombing, which is the presence of large voids in concrete caused by inadequate consolidation.

Summary

There are many different evaluation methods and each provides specific information that can be used to identify or help identify the cause of a specific defect; thereby allowing for proper design of a repair method to ensure a quality repair and mitigation of further damage. Using visual examination as the initial evaluation method allows for identification of the information factors that are needed to complete the evaluation and repair.

No comments:

Post a Comment