A blog comprises of my everyday hurdle, problems and solution, so anyone who doesnt have experience in such work may have at least an idea or reference

Wednesday, 30 May 2018

Friday, 25 May 2018

Wednesday, 23 May 2018

Trial Assembly of Steel Box Girder and Cross Beams

Trial Assembly

General

The trial assembly will be carried out for all bridges at Workshop to ensure that erection

tolerances will be achieved after the fabricated components are erected and assembled at

site. The trial assembly shall be performed according to the trail assembly plan.

The trial assembly shall verify that the individual elements have the shape to fit exactly

into adjoining elements. Also, the trial assembly shall verify that the camber aimed at, or

prescribed, actually exists, and that the geometry is correct.

Procedure

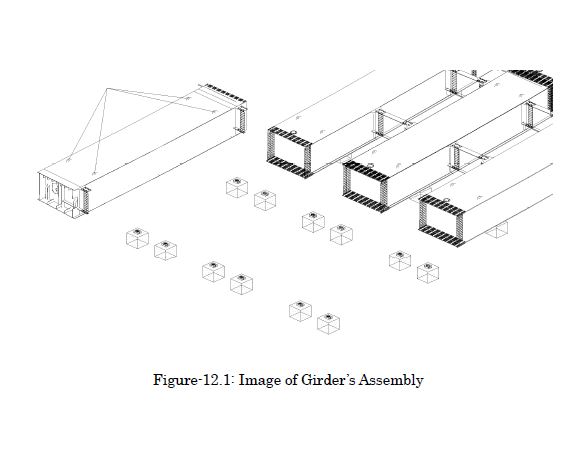

In the method of actually combining members it will be conducted with a support so

that each member is as being in the state of non-stress as shown in Figure-12.1. Temporary

bolts and drift pins must be used and solidly tightened up in the portion of on-site

connection of the primary part out of respective combined members. Additionally, when a

mismatch between the base material and connection plate arises, the necessary repair must

be performed.

but shall not injure the material. The marking of components shall be in accordance with

that shown in the fabrication drawings. Each trial assembly shall be completed and

measured.

All bearing position is checked to set templet of bearing form in soleplate

Subscribe to:

Posts (Atom)