Introduction

During the Material Receiving Inspection of the 5th Shipment at the Storage Yard of Gumti site, damages with plastic deformation had been found in the SCCD material delivery from J&M located in Myanmar. The bent damages were recorded in the NCR submitted to the Engineer for notification and inspected/witnessed by the Engineers representative during the RFI inspection. Investigations have been conducted to determine the root cause of the damages on the SCCD. The result of the investigation think that it was caused by rough handling during transportation in Chittagong port by the person who handled the SCCD from unloading, loading and shifting the SCCD from one place to another

Additionally, this method statement can be used for similar delivery damages that may occur in the succeeding material receiving inspection deliveries.

Damage Type Confirmed in the Material Receiving Internal Inspection

Method Statement of Repairing Damages

No.

|

Equipment and Tools

|

Qty

|

Remark

|

1

|

Gas Burner set

|

1 set

|

Oxygen and Acetylene or propane

|

2

|

JIG

|

1 set

|

|

3

|

Jack and Grinder

|

1 no.

|

Jack:50t

|

4

|

Arc-welder and material

|

1 set

|

LB-52

|

5

|

Lever Brock

|

2 no.

|

1.5t or 0.75t

|

6

|

Painting tools

|

1 LS

|

Include brush and sand paper

|

7

|

Paints

|

1 LS

|

Include Thinner

|

Summary Schedule

No.

|

Activity/ Day

|

Days

|

1

|

2

|

3

|

4

|

5-11

|

12

|

|

1

|

Preparation works

|

||||||||

2

|

Repairing works

|

3

|

|||||||

3

|

Checking(Internal)

|

1

|

|||||||

4

|

Touch-up Paint

|

7

|

|||||||

5

|

Dry Film Thickness

|

1

|

|||||||

Flow Chart

Repairing Work for Bended SCCD PL

If cold-straightening method shall be used, the Contractor shall provide the following equipment, the lever block, jack, JIG (refer to sample pictures below) shall be used depending to the severity of damages. The Contractor shall use other necessary tools applicable if necessary deemed by the QA/QC Manager and his Team during the in-process and final inspection of the repaired SCCD.

If straightening shall be carried out by heating, the steel shall be heated not higher than temperature of 600℃. The temperature shall be measured by thermal control crayons. The SCCD shall be re-bended until the SCCD reaches the original position and design or until acceptable tolerance is attained. After heating, the material shall be cooled slowly in air without any forced cooling method.

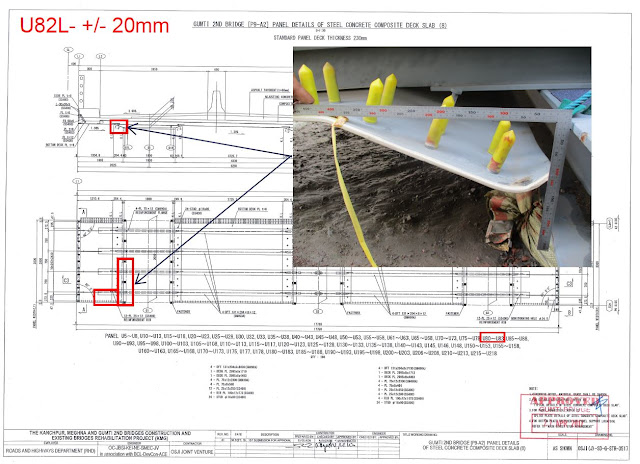

After the repair of the damaged SCCD, internal checking shall be carried out and checked following the table below for the allowable flatness of SCCD panel required by the Specification table below.

After the repair of the damaged SCCD, internal checking shall be carried out and checked following the table below for the allowable flatness of SCCD panel required by the Specification table below.

Damaged bolt shall be removed by Grinder. The removal of bolt shall be clean and free from foreign materials. After removal of the bolt, the surface shall be checked by visual inspection. If notch or gouge occurred in the area of steel, it shall be removed by grinding method.

Welding material shall use the “LB-52 (A low-hydrogen type of covered electrode)”. Drying time of the welding material shall be limited to 4 hours. If the drying time exceeds 4 hours resulting for breaking a seal or the electrode have absorbed moisture, material should be dried naturally.

Welding Procedure shall be carried out by SMAW (Shielded Metal Arc Welding) in flat welding position (1G).

Quality Control Plan

No comments:

Post a Comment